Railing Infill Panels for Dummies

Table of ContentsExamine This Report on Railing Infill PanelsWhat Does Railing Infill Panels Do?The Railing Infill Panels Statements

Infill wall surfaces are normally installed on website as specific aspects that are pre-cut to length yet they can be pre-fabricated as big panels with the cladding already affixed. The exact same elements may be made use of for interior separating wall surfaces, but below the primary issues are fire resistance and also acoustic insulation rather than resistance to.loading. A small inner pressure is made use of in the style of internal dividing walls. @&&h2@ [leading]

Types of

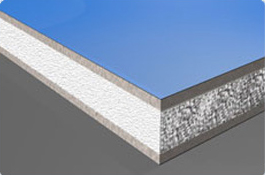

infill walling @&&/h2@ Numerous kinds of building and construction can be employed to develop infill walls that cover in between floors in steel or concrete buildings. Traditionally, infill walls utilized stonework or wood, yet the modern type of building and construction uses light steel C areas that span between the floors as well as around openings. The C areas are positioned at a routine spacing depending on the outside faade products, and also at a spacing which is also compatible with basic plasterboard and also sheathing board sizes. @&&h3@ [top]

The Single Strategy To Use For Railing Infill Panels

The light steel parts made use of in infill wall surfaces includes C sections and U sections of. railing infill panels.

75 to 150 mm deepness that are cold roll-formed from galvanized steel strip of 1. 2 mm thickness defined to BS EN 10346. The galvanizing( zinc layer) offers outstanding resilience. The C areas are put at 400 or 600mm spacing as well as pairs of C areas may be utilized alongside big openings. Wall surface panels can be pre-fabricated as storey-high systems or, a lot more often, are website assembled from C areas that are delivered cut-to-length. The second method is typically the only solution in restoration applications where tolerances in the original building and construction have to be fit. Site set up light steel walls in a steel framed structure Pre-fabricated light steel infill wall surface panels in a steel framed building Infill wall surfaces include a bottom' track' connected to the floor and a leading' track' connected to the underside of the floor over. This motion is important in concrete frameworks, where 2 to 3 mm reducing of the concrete structure per floor can occur in time in addition to regular structural motions. The upright C sections are made to span 2. 4 to 5m between floors, as well as to stand up to wind lots or other tons in bending. The straight C areas over and also below the windows transfer tons back to the vertical C sections. 1 or 2 layers of' fire-resistant' plasterboard( adhering to BS EN 520, Type F) to the inner face offer for as much as 90 mins fire resistance to the light steel infill wall. @&&h3@ [top] Light steel separating walls @&&/h3@ Pre-fabricated light steel wall see this site surface panels Light steel separating wall surfaces use similar parts to.

Railing Infill Panels - Truths

acoustic or fire functions therefore are single fallen leave wall surfaces making up C sections of 55 to.

90mm deepness, relying on the wall height, with solitary layers of plasterboard on each side. @&&h3@ [leading] Masonry infill walls @ & &/ h3 @. Wall surfaces built from clay bricks or cinder block are the typical form of infill wall building. Nevertheless, using block-work infill walls has lowered recently due to the fact that it is an untidy and also time consuming website procedure, and needs a huge quantity of materials taking care of. From a design perspective, strengthening posts are needed alongside large window openings, as the stonework is not completely solid to withstand the high local wind lots beside these openings. @&&h3@ [top] Concrete infill wall surfaces @&&/h3@ Pre-cast concrete infill wall panels Concrete infill wall surfaces are generally in the form of large precast concrete panels that are storey high as well as usually of a width determined by the column spacing. These large panels may be leading installed or bottom supported. They normally birth Look At This onto the floor slab

making use of a boot plan, and are bolted back to the structure on the level over or below. Indispensable panels may be dressed in other products( generally concrete panels are outfitted in stone). Panel weights of about 300kg/m are common, with panel sizes of in between 3 as well as 9m and height of 3. 2m. The optimum dimension of panel is restricted by transport factors to consider and crane lifting capability( both on website and at the concrete works). 15 to 20 tonnes are regular maximum weights of precast concrete panels. @&&h3@ [top]. Hardwood framed infill wall surfaces @&&/h3@ Timber infill walls utilize standard lumber areas of investigate this site 90.

and also 140mm deepness to span 2. 4 to 3. 6m between floors as well as are similar in form to light steel infill walls. Lumber sections are cut to length and also are positioned at 400 mm or 600 mm spacing. The disadvantage of wood in contrast to steel is that it is not as solid and it is not possible to use it in tall walls or in walls with big openings. @&&h2@ [top] Advantages of light steel infill and also dividing wall surfaces @&&/h2@